|

| Source : _www.rurystalowe24.com |

Pipes are fundamental for the transport of oil, gas, water and another fluids over long distances. pipes are exposed to extreme conditions, whether they are buried underground, underwater or on above ground lines. For the durability and resistance, therefore the external layers play an important role.

The most important task for the outer coating of the steel pipes is to protect against corrosion. When laid in the earth or in the water pipelines, the protective lacquer layer is applied directly to the metal surface. With layer thicknesses between 300 and 500 microns, it provides effective protection against corrosion and other environmental influences for a long time. They are usually coated with an epoxy powder coating. For this purpose, the pipes to about 200 degrees Celsius to be heated, so that the electrostatically applied powder can fuse to form a homogeneous and solid layer. Immediately thereafter, the pipe is wrapped with a polyethylene film before it is usually cooled by a water wall again, so it can be loaded and transported. The polyethylene layer ensures particularly when under water or in the ground laid pipelines for additional protection against mechanical influences.

Additional layers of coating are used for additional protection, for weight to help the pipeline remain laterally stable on the seabed, or for providing insulation. A multi-layer coating is generally used in cases where the external environment tends to easily wear out the external coating (e.g., pipeline lying on top of rocky soil, calcareous material, etc.). Insulation is provided to maintain a higher temperature of the flowing internal fluid compared to the ambient. Depending on the external environment and on the location or use of the pipeline, a single-layer coating or a multi-layer coating is required.

Material

Coating material must meet the requirements of International standards & codes CSAZ245.21-10.

Powdered Epoxy Primer

Powdered epoxy primer layer will protect the surface of the pipe and used in accordance with the design temperature. Layer of powdered epoxy primer must be supported by the manufacture adhesive to conform to the adhesive. Powdered epoxy primer layer must have properties in accordance with the requirements in Table 1 of CSA standard Z245.20 below.

|

| Epoxy Powder Properties |

Adhesive

The adhesive material should be able to glue the wall between the two surfaces, steel and polyethylene coating, physical and mechanical properties to be possessed (without dye) is: |

| Adhesive Properties |

Polyethylene

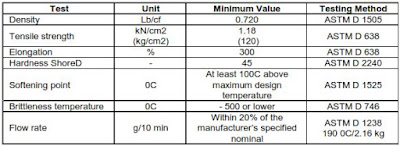

Polyethylene is a polymer made from ethylene as a main material and other materials in a very small amount of lubricant, antioxidant etc. So that the nature of weather resistance increases, polyethylene must be mixed with carbon black and dye dissolved evenly. Physical and mechanical properties that must be held are as follows:

|

| Polyethylene Properties |

Coating Installation

The outer surface of the pipe must be free of oil, grease, dust, rust, dirt and moisture. Pipe surface moisture must be maintained at a temperature of + 3 Degree Celsius above the dew point and not exceed 150 Degree Celsius during blasting, cleaning and inspection.

Dirt cleaned by sand blasting until it reaches the level of Cleanliness SA 2 - ½ by Swedish Standards SIS 05 5900. The surface of the pipe which has clean then heated (as per the coating material manufacturer's recommendation). Epoxy sprayed onto the entire surface of the pipe, then apply adhesive on the entire surface of the pipe and then coated with polyethylene by means of extrusion (ways and equipment must conform coating material manufacturer's recommendations). After the coating is completed, the pipe that had been coated with PE cooled with water (temperature ≤ 70 Degree Celsius).

Thanks for sharing this with us! Some really amazing features.

ReplyDeleteepoxy pipe coating

Concrete Epoxy Coating

ReplyDeleteAt New Jersey Garage Design, we offer one of the best garage solutions and services such as Concrete Coatings and Concrete Epoxy Coating with a wide variety of colors and configurations to meet your needs.

To put it in a nut shell your boxing gloves need to be tailored to fit your needs, whether you're a man or woman, a casual or serious boxer. Think of them as an extension of yourself! cheap glove box

ReplyDeletenice to see your content but you can also check epoxy floors

ReplyDelete